Introduction

The GEOTECHNICAL ENGINEERING Laboratory is equipped with facilities to carry out many types of tests on soils. These include testing of a large range of sample sizes for compressibility, shear strength and drainage properties. Basic equipment for soil dynamics field and laboratory experiments, including the resonant column apparatus, are also available.

Click Here to visit Geotechnical and Centrifuge Laboratory's Website

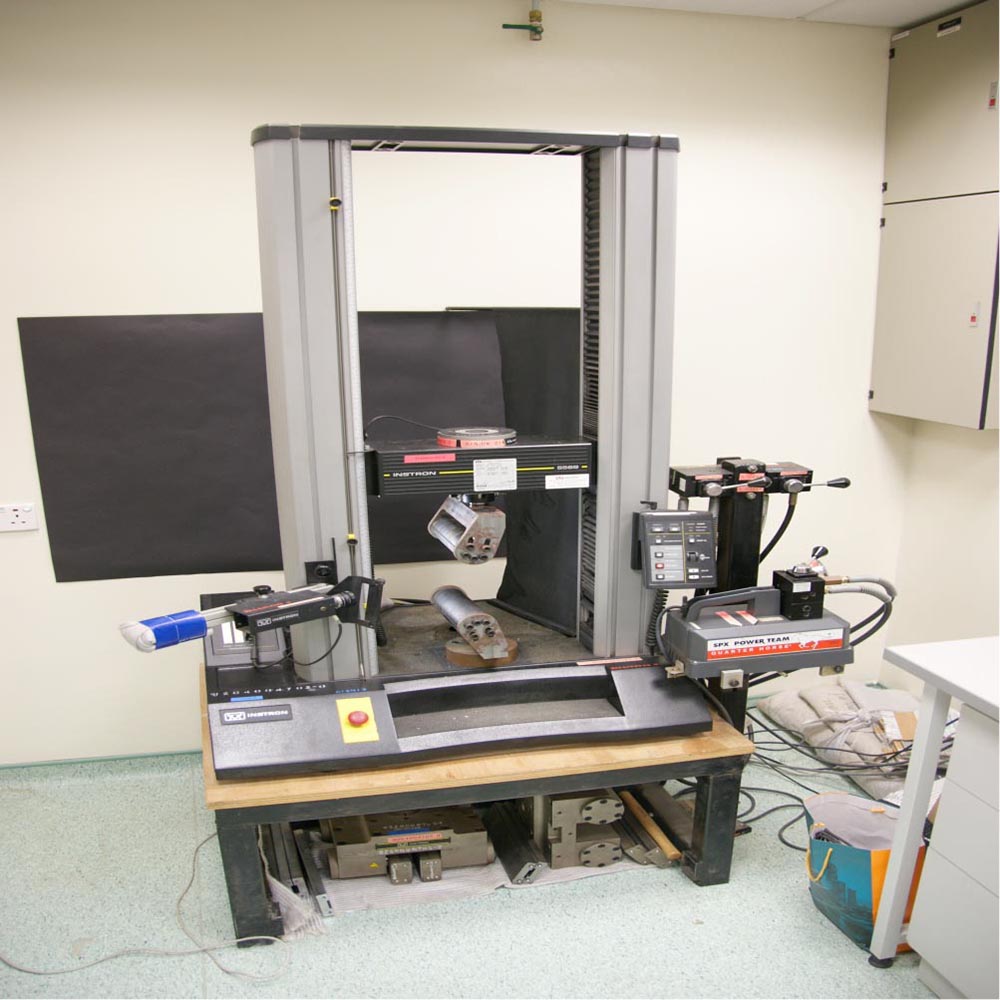

INSTRON Machine for high strain & tensile strength measurements of fabric materials up to 50kN with a wide range of extension rates.

Geotechnical centrifuge for physical scaled modeling of prototype soil-structure problems up to 200g with payload capacity of 40 g-ton.

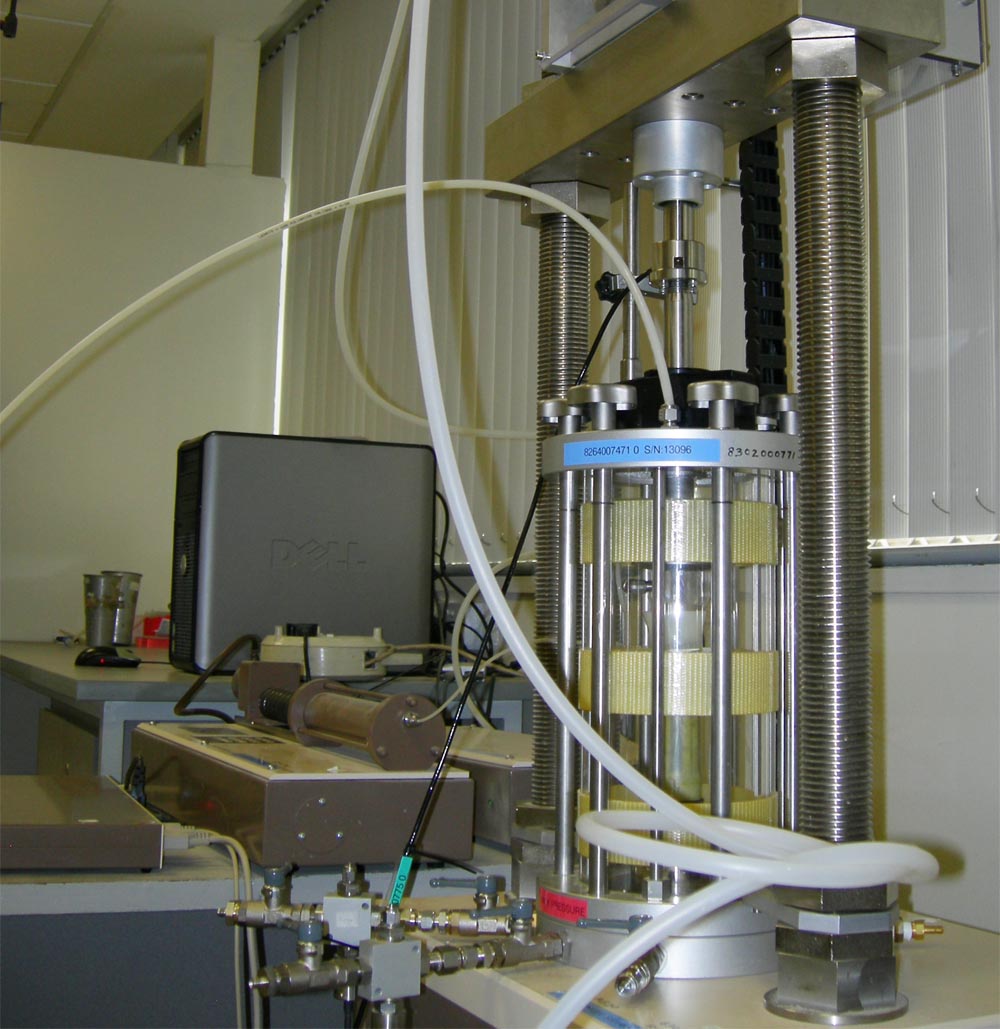

Triaxial setups for sophisticated soil sample stress path tests and cyclic loading tests.

Resonant Column Apparatus for small strain dynamic soil testing.

Introduction

The Structural Engineering Laboratory comprise: Structures Laboratory, Concrete Laboratory, Wind Tunnel Laboratory These laboratories support research and teaching activities of the Structural Engineering Programmes, Offshore Engineering Programmes, Centre for Construction Materials and Technology and the Centre for Offshore Research and Engineering.

Click Here to visit Structural and Concrete Laboratory's Website

Drop weight system with drop heights up to 5 m and drop weights up to 1 tonne for impact tests.

A 10 MN servo-hydraulic actuator and testing frame for testing columns up to 5 m high and beams, up to 2 m wide and 5 m long

High temperature furnace with provision for loading of specimen at elevated temperatures up to 1200 °C.

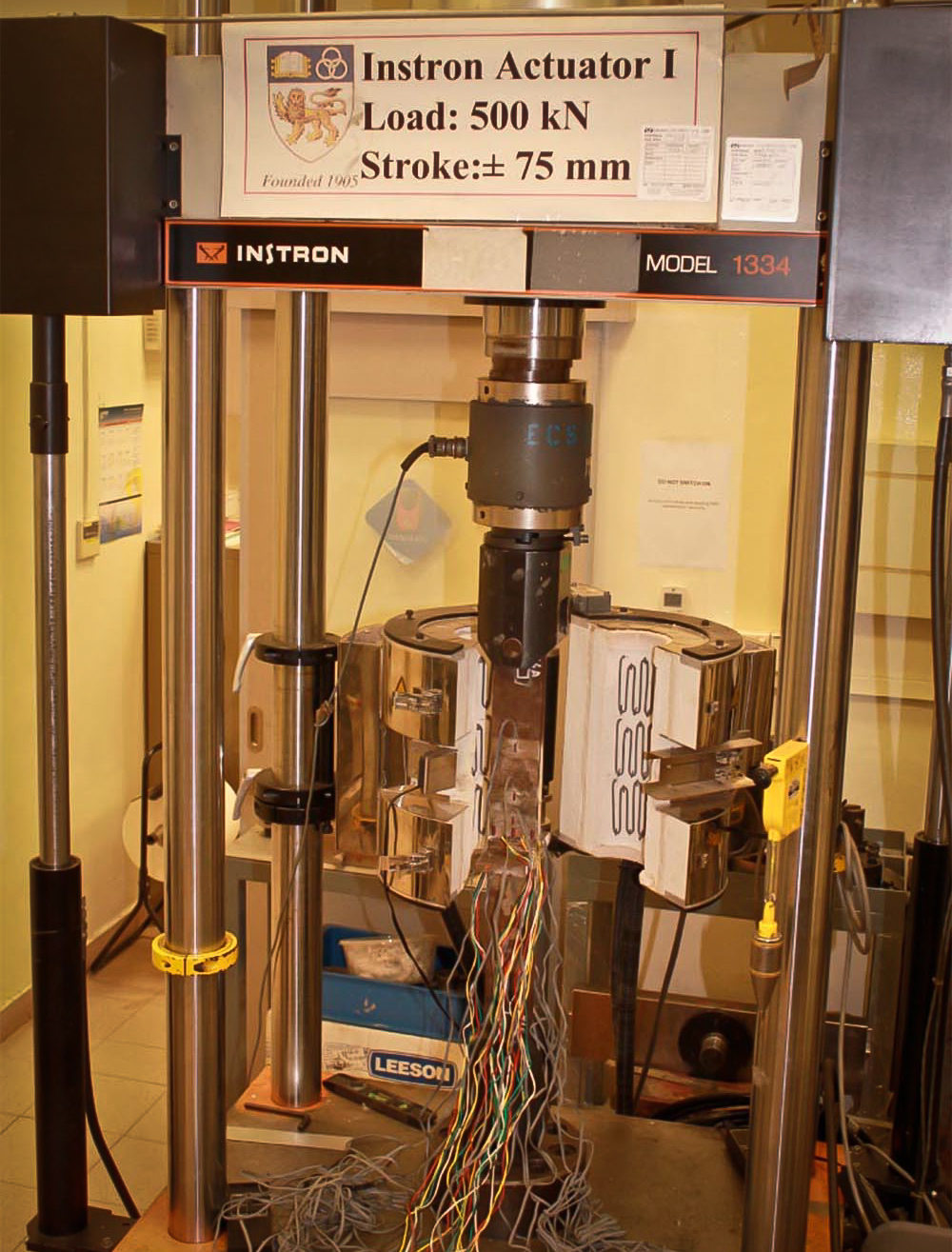

Universal testing machines with capacities of 300 and 500 KN for static, cyclic, and high strain rates tests.

Introduction

The Impact Mechanics Laboratory is equipped with facilities for dynamic materials testing, low velocity structural and product drop tests, ballistic projectile penetration tests and computational simulation of dynamic processes.

Click Here to visit Impact Mechanics Laboratory's Website

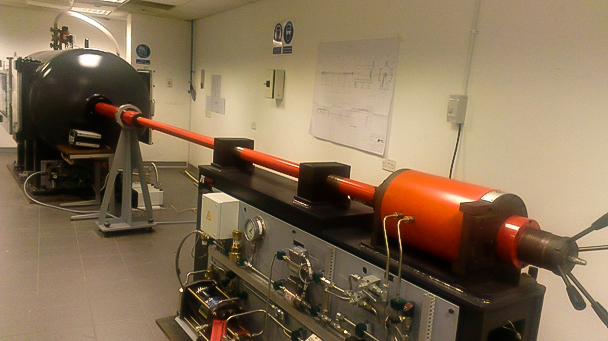

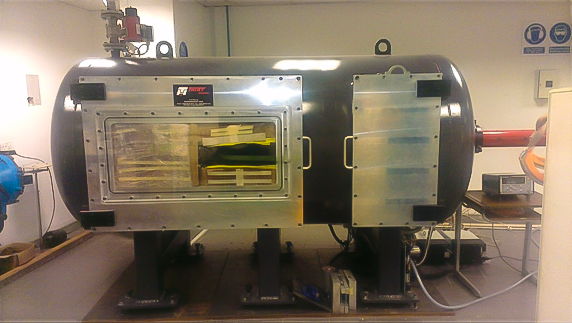

The Gas Gun Facilitiy comprises three main components – an 8.5-litre reservoir that can be charged by helium or nitrogen gas, a 5m long barrel, and a target chamber (3m long, 1.3m in diameter) to accommodate specimens up to sizes relevant to concrete/rock.

The target chamber incorporates a vacuum and venting system. Before a test, the chamber is evacuated; after a test, the venting system is activated to remove dust particles.

Operation of the device is conveniently carried out from a control panel, which allows test parameters to be set by the user. For safety, the control panel is located outside the test room.